China foundry is able to create good engine, but due to a number of factors design, equipment, materials, from the world's top there are still gaps.

So completely independent from China to design and manufacture outstanding engine still has not a small distance.

design gap is present, no drawings, difficult to imitate

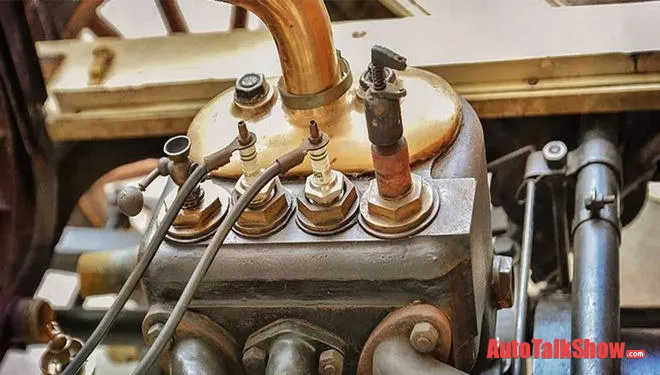

China's auto industry started late, many companies design the engine, or called research and development. At first people are relying on to buy things, famous, good engine apart to reverse development, suggesting research and development.

For example, BYD, Geely, Great Wall, FAW, are developed through reverse Toyota, Volkswagen car prices of these old star product.

in the complete absence of the drawings, the reverse development, do is the size of each part of it to measure up. Reverse data obtained, there will be little error.

There 'research and manufacturing precision engine performance relationship, "the paper stresses above.

have experimental data: the accuracy of a piston engine, the cylinder member and the like of the phase difference error of 0.0 millimeters.

1 will almost silk hair so the thickness of the error, it will affect about 2?f the overall performance of the engine.

every component if there are some errors, after the entire engine to do it again, and the original vary greatly.

can be said to be a replica of a piston is easy, but you want in the absence of drawings, a replica of the engine such relatively sophisticated industrial products, is really very difficult.

There is an article that compared what the Chinese production 4GB2.3C engine, the performance gap between import Mitsubishi 4A90 and generic objects.

mechanical efficiency, speed range of everyday noise control, engines are produced in China to be behind a number.

China R & D engine forward greater difficulties

In addition, trying to reverse the results of research and development to get converted to their own things, digestion and absorption further develop positively, difficult also great.

like the time before school, do not touch the subject, then copy the students to see, copy, is not it?

copied classmates, students see the answer: "Oh" was such! Well I will! Suddenly realized that this subject much better than this, right?

But the same type of problem, we have minor physical condition, the parameters for a change, in front of multiplication, subtraction becomes the first front, then the back of the multiplication, and will not do.

This is the problem we now encounter.

China's car prices in engine design above recount, basically get rid of completely reverse imitation phase.

By the internal combustion engine and a number of famous foreign design institutions, to hire foreign experts in design, research and development centers worldwide range features what various ways, be gradually have their own R & D system a.

engine performance and quality than earlier products, is really a big one on the stairs, much better. But overall, foreign top products and there are still gaps.

For example, Changan Automobile, 1, 2 years ago, has experienced an increase in the problem of engine oil and the like.

Honda acclimatized you can say that we Chinese produce something of their own design, can not be said to be acclimatized it! right?

China we produce something of their own design, I can only say that there are many areas for improvement, right?

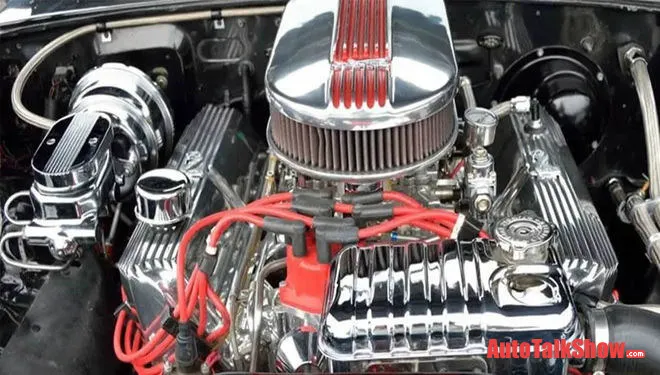

China is already the world's top manufacturing level

With foreign equipment has been able to produce top-engine

Talking about this, we do not feel like I'm giving everyone discouraged, if you look at manufacturing, manufacturing is already the world's top level.

You say foreign aid equipment, or design, etc., can already produce a top-level engine.

But to design and manufacture their own words, relatively speaking, more difficult, it is: someone else to help, first in the world; no one else to help, still owe tone.

completely on our own, put it out 100?f a world's highest level, it is still more difficult.

We take a production engine block, cylinder head, the more critical parts of die-casting technology to give an example.

FAW Foundry Co., die casting plant equipment is already very good.

3D design ratio of 95?after a 3D design, 3D virtual assembly detection technology, development die process, the flow field, the temperature field simulation, the strength is already very good, do not lose any top international of technology.

But the key question is, which of these measuring devices and equipment to those portions of the core, still comes from abroad.

some coordinate measuring machine from Germany, England high-speed scanners.

This is a bit like: We now academic performance has been very good, business is also making a lot of money, but come to the teacher, with the master, also are abroad.

Shenyang Brilliance BMW engine plant, even within the world's first all-BMW engine plant technology, casting, machining, assembly, are all capable of this factory. It also can be sold back to Europe to go.

BMW local assembly, the engine is now also part of the above logo that says "made in China" a. Germany, have been to this sake.

but the entire production line, mostly imported advanced equipment: imported robotic arm, Swiss ABB company, each worth at least 300,000 yuan.

This factory B series engine, 50?f the parts, imported from China producing 100?or a distance.

Chinese production equipment from world-class standards is still a gap

So, why we do not own the equipment?

mainly because Chinese production equipment, now does still exist a gap and abroad.

Take this high-end manufacturing industry can not do without advanced CNC machine tools, for example, there are the paper, "Current Status and Countermeasures China CNC machine tool production," say it.

foreign machine MTBF MTBF of 2000 hours, 2000 hours before easily broken; widespread in China around 1000 hours, a little better is 1500 hours up and down.

If all use their own equipment to produce all parts, can not achieve such high quality, it may be problematic.

"Well," Think of the difference between the point in time. not like this.

You have to run all the equipment together when not a problem, then you create a good come. What are you making half, A problem, no, come back; B a problem, come again.

It is no more good times together in the stack, which is annoying, tone tone also very tired, is such a meaning.

However, these assumptions are, in fact, "patchwork" approach is currently the practice in the automotive industry.

automotive economy of the world to engage in such a process are: Japan bulb, the German engine, China's door, are also put together in such a fight.

unlikely that all things, even the production equipment is the hands themselves.

So, this is a bit like a "pseudo-proposition", and we Chinese car prices Ye Hao, Ye Hao things do not pick up all the things themselves, because they still do not do it abroad a.

This is like our clothes, buttons, zippers, thread, sewing machine, fabric clothes are produced by different companies.

I can not say that today is Uniqlo, from the outside of the packaging plastic bags, cardboard boxes, to the inside of the clothes, stitching all Uniqlo production impossible.

You look at Tsingtao Brewery, Tsingtao Brewery beer cap is not his own production, as the same.

even if made out, the market will not accept

We went in front of it, even if we just have the ability, we have made it out of everything "made in China" . From the fabric to the sewing machine to the outside we have, we have made out.

Even doing so, it may not necessarily be able to accept the market, this is very very depressed people's problems. Because repairer is a whole, it is all the technology needed to keep pace with development.

and the famous "bucket theory" is very similar, how much water can hold is the shortest of the board's decision, not the longest that one.

no matter how good your engine, gearbox bad if you how to do it? Cooperation between the gearbox and the engine not how you do it? This is very troublesome.

You have done well with the engine gearbox when the interior is not good, how do you? You have done well interior, exterior does not look good how to do?

These are very good-looking you, your brand and how to do it loud enough? Your brand is very loud when people said you cost is not high enough how to do?

huge piles of things, which is not cost-effective thing.

So there was little car prices just to make it a particularly good, the perfect engine to make every effort, to abandon all other everything.

What's more, now many are wondering car research and development of new opportunities for the energy sector.

Some car prices on the internal combustion engine Higurashi Western Hills, and access to research and development or funds, there is even less.

Most consumers consider buying a car more intuitive feel

When coupled with the majority of Chinese consumers consider friends to buy a car, but is: how this kind of car space ? Look good or bad? Price is really not affordable? I said earlier, those things.

real performance, the engine a little better, a little bad, nobody throttle foot down when it comes to the amount of: 5 degree I stepped on is how much? I stepped 10 degree is how much? There are few friends to buy a car.

It's like, is also selling a tomato scrambled eggs, tomato scrambled eggs that look fresh is not bright, not tasty, this dish servings are not so big.

This ratio is not imported tomatoes, eggs are much more important hen eggs in soil or ordinary eggs to come up.

Chinese industry and foreign top level there is a gap

On the whole, Chinese industry started relatively late, although these years to catch up, but from development to production, and indeed foreign top level there are still gaps.